In the modern packaging industry, aluminum and tin cans stand out as quintessential elements for a myriad of applications ranging from food and beverage storage to decorative and holiday tins. Understanding the nuances between these two materials is paramount for businesses looking to make informed choices regarding their packaging solutions. Through my extensive experience in the aluminum tins sector and as an expert in this field, I will guide you through a comprehensive comparison, highlighting not just the differences but also the unique advantages each material brings to the table. This knowledge becomes particularly valuable when sourcing the right supplier for your packaging needs.

Differences between Aluminum and Tin Metal

Understanding the fundamental differences between aluminum and tin metals is crucial for businesses when choosing the appropriate material for packaging solutions. Each metal offers distinct characteristics that can significantly impact the product’s protection, sustainability, and appeal.

Chemical Properties

- Aluminum: Aluminum is a highly reactive metal in its pure state, however, it develops a thin oxide layer when exposed to air, which prevents further oxidation. This natural barrier makes it inherently resistant to corrosion and thus an excellent choice for protecting sensitive products. Aluminum’s chemical composition allows it to be lightweight yet strong, capable of resisting significant pressures.

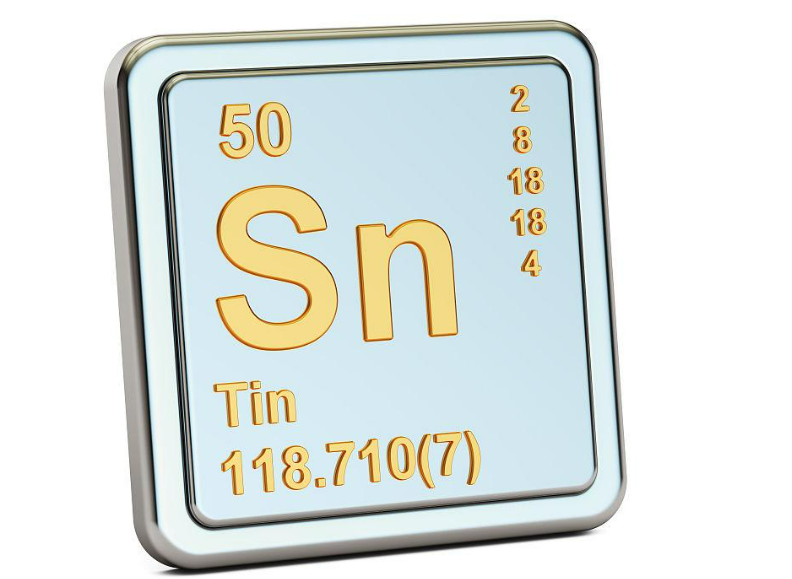

- Tin: Tin, unlike aluminum, is less reactive with atmospheric oxygen, which makes it less prone to forming an oxide layer. However, its coating on another metal, such as steel, provides excellent corrosion resistance. Tin’s chemical stability, especially in food-safe tin plating, prevents the metal from altering the taste of food items stored within.

Physical Properties

- Aluminum: Its physical attributes include a low density and the ability to be easily worked into various shapes through processes like rolling, extruding, and forging. These characteristics make aluminum highly versatile for producing everything from thin, lightweight beverage cans to aluminum screw caps.

- Tin: Tin’s physical properties include a lower melting point compared to aluminum, which makes it easier to cast or work with at lower temperatures. This property is particularly beneficial when tin is used for coating other metals, offering additional durability without significant weight.

Environmental and Economic Aspects

- Aluminum: The recycling process for aluminum is more energy-efficient compared to its extraction and initial production, making recycled aluminum less costly and more environmentally friendly. Its ability to be recycled indefinitely without losing quality makes it a sustainably superior choice, despite the high energy use in its initial production.

- Tin: Tin cans, typically steel cans coated with a thin layer of tin, can also be recycled. However, separating the tin from the steel requires additional steps, possibly making the recycling process more complex and slightly less efficient than aluminum. Economically, tin can be more cost-effective upfront due to less energy-intensive production processes compared to aluminum.

Understanding Aluminum and Tin Cans

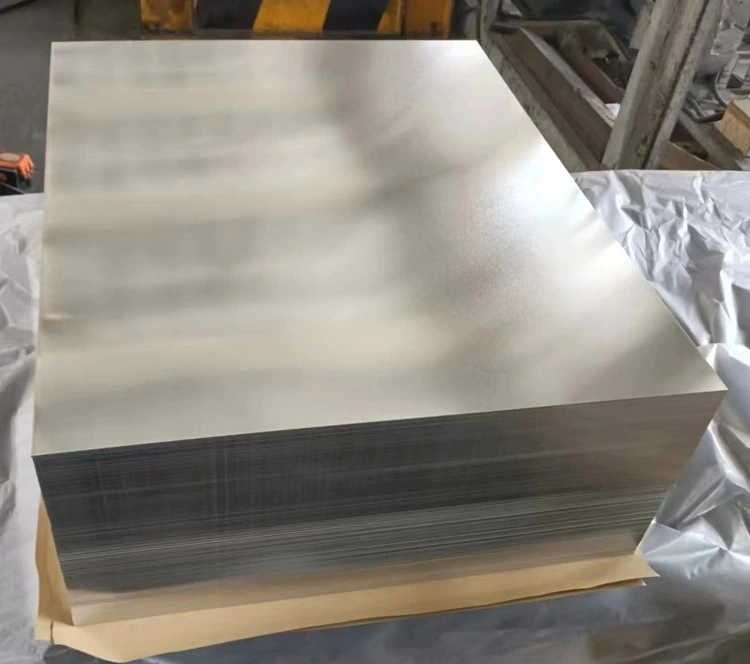

Before delving into comparisons, let’s clarify what we’re talking about. Aluminum cans are lightweight, durable containers made from aluminum, known for their excellent corrosion resistance and recyclability. Tin cans, on the other hand, often refer to steel cans with a thin tin coating, combining the strength of steel with the corrosion-resistant properties of tin. Both have broad applications in packaging, from food tins to decorative tins, and special occasions like holiday tins.

Key Differences Between Aluminum and Tin Cans

Material Properties

- Durability and Weight: Aluminum cans are remarkably lightweight and possess a high strength-to-weight ratio. This feature not only makes them efficient for transportation but also appealing for various packaging needs. Tin cans, due to their steel base, are heavier and extremely durable, suitable for products requiring sturdy packaging.

- Corrosion Resistance: Both materials boast impressive corrosion resistance. However, aluminum naturally forms an oxide layer when exposed to air, providing inherent protection against corrosion. Tin cans rely on a thin layer of tin to prevent the underlying steel from rusting.

- Recyclability: Aluminum stands out for its recyclability, with the ability to be recycled indefinitely without losing its quality. Tin cans are also recyclable, but the process is slightly more complex due to the need to separate the tin and steel.

Applications in Packaging

- Food and Beverage Packaging: Both aluminum and tin cans are extensively used in food and beverage packaging. Aluminum is preferred for beverages, thanks to its excellent thermal conductivity, making it ideal for cooling. Tin cans are widely used for canned foods, offering robust protection and a long shelf life.

- Specialty Packaging: For unique packaging needs, such as candle tins or cosmetics, aluminum cans offer a modern, high-quality appearance with the option for anodizing to create various colors and finishes. Tin, with its vintage appeal, is perfect for decorative tins and holiday tins, where aesthetics are crucial.

Cost Consideration

The price of aluminum and tin cans fluctuates based on global metal prices. Generally, aluminum tends to be more expensive due to its raw material costs and the energy-intensive production process. However, its lightweight nature can lead to savings in transportation and recycling, potentially offsetting the initial cost. Tin cans, often being more economical, cater to businesses looking for cost-effective packaging solutions without compromising on durability.

The PackSar Advantage

At PackSar, nestled in the heart of Guangzhou, China, we pride ourselves on being at the forefront of innovative packaging solutions. Our state-of-the-art facility manufactures both aluminum and tin cans, catering to a diverse range of industries.

Why Choose Us?

- Range of Products: From food tins to decorative and holiday tins, our extensive product offering meets all your packaging needs.

- Customization: We understand that branding is key. Offering a myriad of customization options, including printing and embossing, we ensure your packaging stands out.

- Sustainability: Committed to environmental stewardship, we focus on producing recyclable tins and encourage our clients to consider the lifecycle of their packaging choices.

- Quality Assurance: Leveraging my extensive experience in the aluminum tins sector, I ensure that every product meets the highest standards of quality and sustainability.

Making the Right Choice

Choosing between aluminum and tin cans boils down to understanding your product’s specific needs, aesthetic preferences, budget considerations, and sustainability goals. Aluminum offers a lightweight, modern solution with superior recyclability, ideal for beverages and high-end packaging. Tin cans, celebrated for their traditional appeal and robustness, are perfect for food storage and decorative uses.

For those navigating the intricate choices between aluminum and tin cans, PackSar emerges as your go-to supplier, combining expertise with unparalleled quality. Embrace the future of packaging by exploring our range and discovering how our bespoke solutions can elevate your brand.